Material Reconciliation Format

Vyapar software has a material reconciliation format used for efficient and effective management. It can be used for material reconciliation, bills, delivery challan, invoices, and inventory management. Avail of the 7-day free trial now.

- ⚡️ Create professional reconciliation with Vyapar in 30 seconds

- ⚡ Share reconciliation automatically on WhatsApp and SMS

- ⚡️ Connect with your parties through reminders, greetings, business cards and more

Highlights of Material Reconciliation Templates

We’ve put in a lot of effort to make sure you get the best template possible

All versions are print friendly

Built From scratch

Include essential invoice elements

Automatically calculate subtotal & grand total amount

Consistently formatted

Download a Material Reconciliation Format For Free

Download professional free material reconciliation templates, and make customization according to your requirements at zero cost.

Customize Invoice

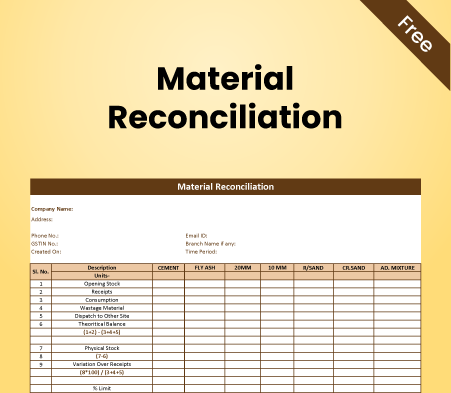

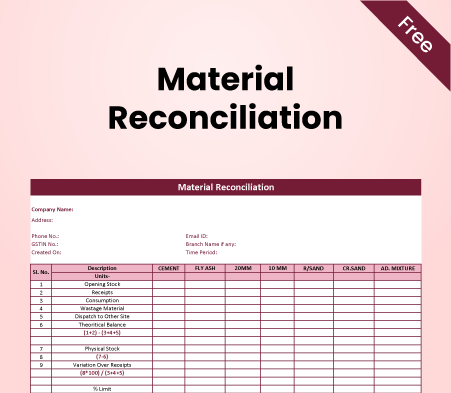

Material Reconciliation Format-1

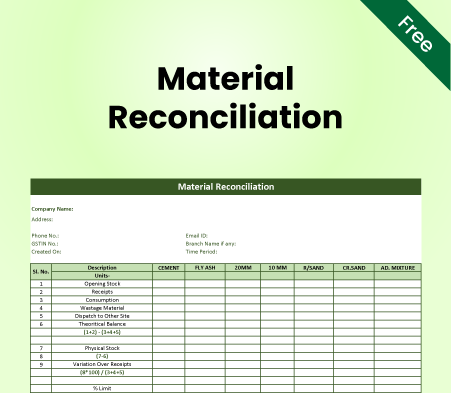

Material Reconciliation Format-2

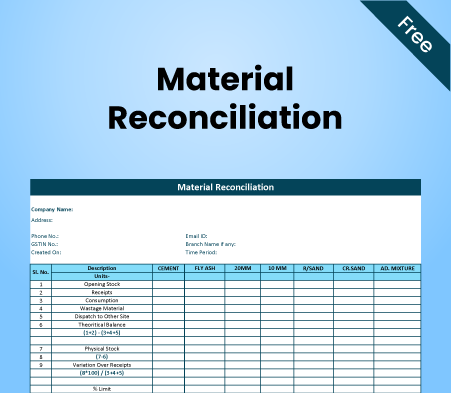

Material Reconciliation Format-3

Material Reconciliation Format-4

What Is Material Reconciliation?

Material reconciliation is a function that is used in the accounting process. It is used to document, maintain, and check the quality of the goods and raw materials used in the production process. It also limits the number of components, quality, and types of features.

These are checked at the beginning and the end of the production cycle of the business. It is done to compare and analyse the variations and utilise the resources during the production process. Material reconciliation is required to accurately measure, maintain, and track the inventory.

Material reconciliation helps the manufacturers to compare the product count with the estimated quantities to plan for further production. It maintains no inefficiency, and the key components are within the valid range of inputs and output. Material reconciliation helps the inventory to be managed and tracked in a seamless and efficient manner.

Material reconciliation format accounting for all the material used in the production process. It is used to determine the efficiency of a manufacturing operation. Material reconciliation is prepared to analyse and verify the number of components used at the end of a production process. It then compares them with the number of features used at the beginning.

It allows businesses to compare the material quantity that flows in with the material produced. Reconciliation of the material components ensures no differences outside the valid range between the input and output. Vyapar’s material reconciliation format efficiently maintains the quality of goods in production.

What Are The Best Practices For Material Reconciliation Format

Material reconciliation format has the potential to enable businesses to manage their budget effectively. The construction industry requires many materials to execute and complete the work. Therefore, the materials must be accounted for with the correct approach in the bills for accounting.

The authorised employers, operators, or supervisors decide the quantity and quality of the materials to be purchased. It is an important role played by quality surveyors and executives. Optimised material reconciliation is necessary to ensure the timely clearance of bills.

Establishing Transparent Procedures And Processes:

Defining transparent processes and procedures is very crucial. It is required to manage and verify the materials in the business. There are some steps that the employer and contractor must undertake.

It includes estimating the quantities and sizes of the amount of materials. Procurement, getting approval on the materials, and checking receipts from the supplier are essential. It is done to manually verify the quality, amount, and specifications of the materials. It also records the materials in the material ledger with crucial characteristics.

Regular Physical Inventory Counts:

Another essential aspect of the material reconciliation format is to check the physical inventory count. It is done before devising the final materials records. The surveyor should calculate the total amount of material in the inventory. This is a crucial step in developing a reliable inventory software system.

It is prepared to avoid miscalculations and misreported data in the stock. The inventory count should be double-checked to ensure the number matches the ledger. The physical inventory could be lower due to resource split among several departments. These double checks allow the manufacturer to compare the utilisation of materials. It is done by analysing records of other departments, like shipment and sales receipts, to detect fraud, differences, or theft.

Consistent Recording And Documentation:

The data should be documented and recorded carefully. Once the inventory records are registered, the operators must compare the current and physical descriptions. The purpose of documentation and consistent data recording is to identify errors.

The errors include missing paperwork, miscalculations, unused items, fraud, human error, and unlisted items. The root of such causes should be promptly checked and examined. It allows the companies to make the required modifications in the production process and gain good results.

Reconciling Discrepancies:

It is essential to record the inefficiencies and differences during the production process. It is an easy-to-understand and accessible material reconciliation format. The operators should focus on analysing the root cause of the issue.

The operators can meet with team members to reason, reconcile records, and maintain reports. Once the root cause of the differences is found, it is crucial to develop a material reconciliation report. The statement should include an in-depth explanation of the disparity with the possible solutions and a comparison with records.

Leveraging Technology For Efficiency And Accuracy:

Consistent checking of inventory and material reconciliation reports is crucial to maintaining accurate numbers. Using modern technology with advanced methods is correct for streamlining the production process. It is done to maximise profits.

Modern technologies are time-consuming. However, they can assist companies in reducing delays, paying employees timely, and enhancing sales. The reconciliation reports should be documented and presented in graphical representations. The material reconciliation format should have an authorised inventory tracking system.

What Are The Advantages Of Using Material Reconciliation Format?

The material reconciliation format is vital to maintain a consistent and efficient production flow. It is one of the critical responsibilities of the materials supervisor. The inefficient monitoring and management of materials can often lead to business losses.

All this may happen due to the need for more material information in production. There are many benefits to creating a content reconciliation format. The benefits are mentioned below:-

Reducing Inventory Errors:

The project managers should consider the raw materials involved in the production process. When the raw materials are not tracked, it can lead to a lack of control.

The need for control over the raw materials involved in the production process is essential. It tracks the errors and mistakes and analyses the materials from the start of the process. It makes it easier to detect any errors beyond the mentioned input and output range.

Improved Decision-Making:

Material reconciliation format helps in improved decision-making through accurate inventory data. It depicts a representation of the data as the foundation of material reconciliation format in Excel.

Manufacturers often define the movement of goods that should be included in the material reconciliation report. The updated information and total amount of material are collected and stored in the database. The operations managers use the correct inventory data to participate in better decision-making.

Saving Time And Resources:

The material reconciliation format helps keep time and resources in production. It identifies the difference between the resource utilisation levels between the two comparison points. The manufacturers may access the data to identify wasted resources.

It moves on to devise a proper plan of action to save time, resources, and money. Regular material reconciliation and regulations make companies more aware of their resources. All these updates help to maximise the overall returns of the companies.

Ensuring Regulatory Compliance:

It is essential to be aware and stay updated with the guidelines and regulations. These regulations are laid out by regulatory agencies and government bodies. So, it is beneficial to ensure regulatory compliance.

By defining the production process, material reconciliation helps businesses to eliminate or minimise penalties. It is done to develop economic projects by complying with strict rules and regulations. It helps to equip companies to scale up and grow better in the future.

Are you a Business Owner?

Take your business to the next level with Vyapar! Try free for 7 days

Try our Android App (FREE for lifetime)

What Are The Challenges Of Material Reconciliation?

An efficient and effective material reconciliation format helps companies in finding potential risks. The risks include data loss, fraud, and late payments. These risks help eradicate the differences in the financial processes.

Other differences, like receivables and variations in the ledger, can also be identified through efficient material reconciliation. It is imperative to enhance the financial planning of the company. It is done by learning the differences and patterns between inventory records and the actual inventory.

However, a few things could be improved with the material reconciliation format. Some of the main challenges associated are listed below:

Human Error:

There are risks of human errors in association with material reconciliation. Human errors are like entering the manual data, calculating inventory, and circulating the data among several departments.

The entire process is often time-consuming on the part of the company. It requires several revisions and verification to reduce any scope of errors. A higher number of human mistakes leads to losing important data and inaccuracies in the output.

Technology Limitations:

Another challenge of preparing a material reconciliation format is technology limitations. It is crucial to use updated, consistent and authorised technologies for material reconciliation format.

The company may use multiple material methods or needs advanced technology. It can often lead to consistent and efficient production processes.

Data Inaccuracies:

Manufacturing companies require accurate, quick, real-time, and transparent data in the database. However, the lack of tools, knowledge, and equipment can often lead to a lack of control over the process. So, efficient and accurate data is necessary for the companies.

The spreadsheets used in the material reconciliation format in Excel need to correct. It should be capable of offering the optimum level of visibility. It can lead to a clearly negative impact on the reputation and credibility of the organisation. However, this can be avoided through the best material reconciliation format and software.

Resource Constraints:

One of the challenges of material reconciliation is resource constraints. The need for more optimum resources also includes the need for highly equipped personnel with expertise—the experience and knowledge to tackle online systems.

The various methods add to the complexity of the system. The company must employ additional resources like software, equipment, and training. It is done to maintain visibility and detect any fraudulent activities like data alteration or theft. It also helps to deal with mismanagement and unnecessary obstacles within the business.

Benefits Of Using Vyapar’s Material Reconciliation Format

Material reconciliation format is an essential part of the manufacturing process. It allows the manufacturers to ensure that the project is operating based on goals and outcomes determined by the company. Reconciliation elevates the production capacity and outputs as manufacturers can compare standard data to actual data. The many benefits of using Vyapar’s material reconciliation format are discussed below:

Build A Positive Brand Image:

Vyapar’s material reconciliation format provides professional quotes and estimates during negotiation. It helps to build a positive and growing brand image. Further, there can be complete disclosure about the deal to build trust.

Vyapar software for material reconciliation format helps to build a professional brand. A professionally built custom invoice and bill can stand out among the competitors. It allows the users to present themselves as a professional seller.

You can create business logo and include, font, style, and brand colours in your invoice. It will help you present your brand’s identity efficiently and perfectly. A buyer is likelier to buy from a seller using professionally customised material reconciliation formats than plain text.

The customised-built quote format looks convincing to buyers and includes all the information you need to make a deal. The data in the invoices can consist of product descriptions, discounts, taxes, and terms of sale.

Vyapar’s GST billing software makes you look professional and helps your customer get detailed information. So, the material reconciliation format of Vyapar software helps to build a positive brand image.

Plan Your Inventory Space:

Using Vyapar’s accounting and billing software, you can manage and track items in your store. It also helps you to set up low inventory alerts. This is done to place advance orders and detect possible theft.

Material reconciliation is essential for businesses, and using Vyapar software for the format is effective. Using the GST invoicing software, you can keep track of available items in your store. The software features can help you detect theft in your store.

Constant periodic checks can also help to detect inventory mismatches using the inventory management feature in accounting software. A professional material reconciliation tool can help you manage items in your warehouse. It may help you organise your stock level per the customer’s demands.

Vyapar’s material reconciliation software is good; you can use the data to create sales reports. It allows you to understand how much inventory is suitable for business based on the sales from last year and current trends.

The billing software and accounting features help track inventory items in all industries. You can also set up alerts on low inventory and ensure you place the order before running out of items in your store.

Track Your Business Status:

Vyapar’s business dashboard makes the entire management production process easy and seamless. You can check the open orders, inventory status, business cash flow, and payment updates in one place. The material reconciliation format helps you to track your business status.

You can manage your business using mobile with the free GST billing software and invoicing tools. Accounting in your business becomes quite simple, convenient, and efficient with the material reconciliation format software.

You can quickly get updates on your business anytime using the business dashboard of Vyapar software. Access to the dashboard is free in the Vyapar software and app. It also offers an adequate facility that includes cash flow, inventory status, payment status, and many more.

A business dashboard makes the entire production process of a business effective and seamless. You can check your stores’ business updates like sales, inventory, and orders step-by-step. The billing and invoicing app helps to analyse your overall business operations.

The billing software helps to save the time required to manage your business efficiently. Using the material reconciliation format of the Vyapar app, you can improve your business strategy timely. It ensures that your business operates seamlessly and effectively. All of this using the material reconciliation format of the Vyapar app.

Manage Inventory Efficiently:

Vyapar software brings the finest inventory management software with effective features. The inventory is efficiently managed by using Vyapar’s material reconciliation format. Using the Vyapar software features like business reports, businesses can track sales.

It helps to understand how effectively inventory has been managed. As the accounting software, Vyapar keeps a record of business data. The material reconciliation format of the Vyapar app is effective. It makes it hassle-free for owners to create an effective strategy.

Using Vyapar’s inventory tracking features helps to maximise the utility of inventory space. Using the billing software by Vyapar, users can check the live status of inventory. Using the inventory tracking features, users can record items and identify them.

The tracking is done using the batch number, slot number, expiry date, manufacturing date, and other details. These are recorded in the software as soon as they arrive. It helps the users have the required stock in place when needed for sale.

For any business, inventory tracking is among the most essential business needs. It helps ensure that all the items are available when they are required for the smooth functioning of the business. Vyapar makes the entire process seamless by keeping an eye on the actual numbers at every transaction.

Receivables And Payables:

Vyapar billing and accounting software allows users to keep all the transaction details. It also helps to track business cash flow seamlessly. Vyapar allows you to track party-wise receivables and payables. Using the business dashboard in the Vyapar app, you can manage and track the money you have received.

You can easily track and observe who did not pay you back. You can set reminders to collect payment dues from these customers on time. The payment reminders can be sent to any party via WhatsApp, email, and SMS. You can provide all types of online payment solutions to collect dues seamlessly.

Also, with the bulk payment reminder feature in the app, you can save time and resources. It is done by sending payment reminders to all your customers in bulk at once. The material reconciliation format of the Vyapar app helps to track receivables and payables.

The GST invoicing software performs automated calculations. Using the cash flow management system, Vyapar enables one to avoid taking too much debt. So, the material reconciliation format of the Vyapar app is effective and seamless.

A clear view of receivables and payables helps keep business cash flow in check. It eliminates the chances of losses due to cashflow issues as you can get a clear idea of declining cash reserves with live data tracking in the business dashboard.

Automatic Data Backup:

Vyapar’s material reconciliation format is 100% safe and secure. The data can be easily stored quickly and accurately. The free inventory software lets you keep your stored data secure by creating local, external or online backups.

Users can easily use Vyapar’s accounting software to recover data quickly. The data stored is encrypted with added safety and security. The Vyapar app is advanced free invoicing and accounting software.

Vyapar GST billing software comes with a hassle-free backup system with the “auto-backup” feature. An automatic backup is created every day after activating the mode on the Vyapar software. So, getting all your data backup is more straightforward, so you would not lose anything.

Most businesses in India use this free accounting software to do the job quickly with added data security. Vyapar material reconciliation format is encrypted with security. It is data encrypted, which allows it to keep the data accessible to the owner. It is done only to enhance safety and security.

Frequently Asked Questions (FAQs’)

Material reconciliation format is an essential aspect of the manufacturing process. It allows the manufacturers to ensure that the operating project is based on goals and results determined by the business.

Reconciliation raises the production capacity and outputs. It allows the manufacturers to compare the standard data to actual data based on the variances and inefficiencies in production.

Material reconciliation should be performed at least twice by businesses. Preparing material reconciliation at the beginning and end of the production process is advised.

Material reconciliation allows businesses to conduct proper checks and verify the data collection of the resource. It assists the companies in finding the difference between the physical inventory records and the material data record.

Businesses may use this data to make the necessary adjustments and changes in the production process. It allows the industry to make the numbers align with each other in the process. It helps to improve the inventory management process of the company.

The critical components of a material reconciliation format include checking the inventory count of materials and comparing the records of it. It also includes documenting the material reconciliation at the end of the production process. This includes checking any differences and finding the leading cause of the issue to optimise the production process.

Material reconciliation is an essential aspect of the manufacturing process. It is important because it can easily detect errors, reduce time, and save money. It also helps to verify the production flow, keep it in check, prevent fraud, and manually alter data. These are the reasons why material reconciliation is essential for the manufacturing process.

Material reconciliation confirms that the main components obtained at the end of the manufacturing process match the input amount of material entered and used. It is a great way to determine the actual yield of integrins, as you can determine the actual output with the expected output.